Fibrecoat 827F

Product description:

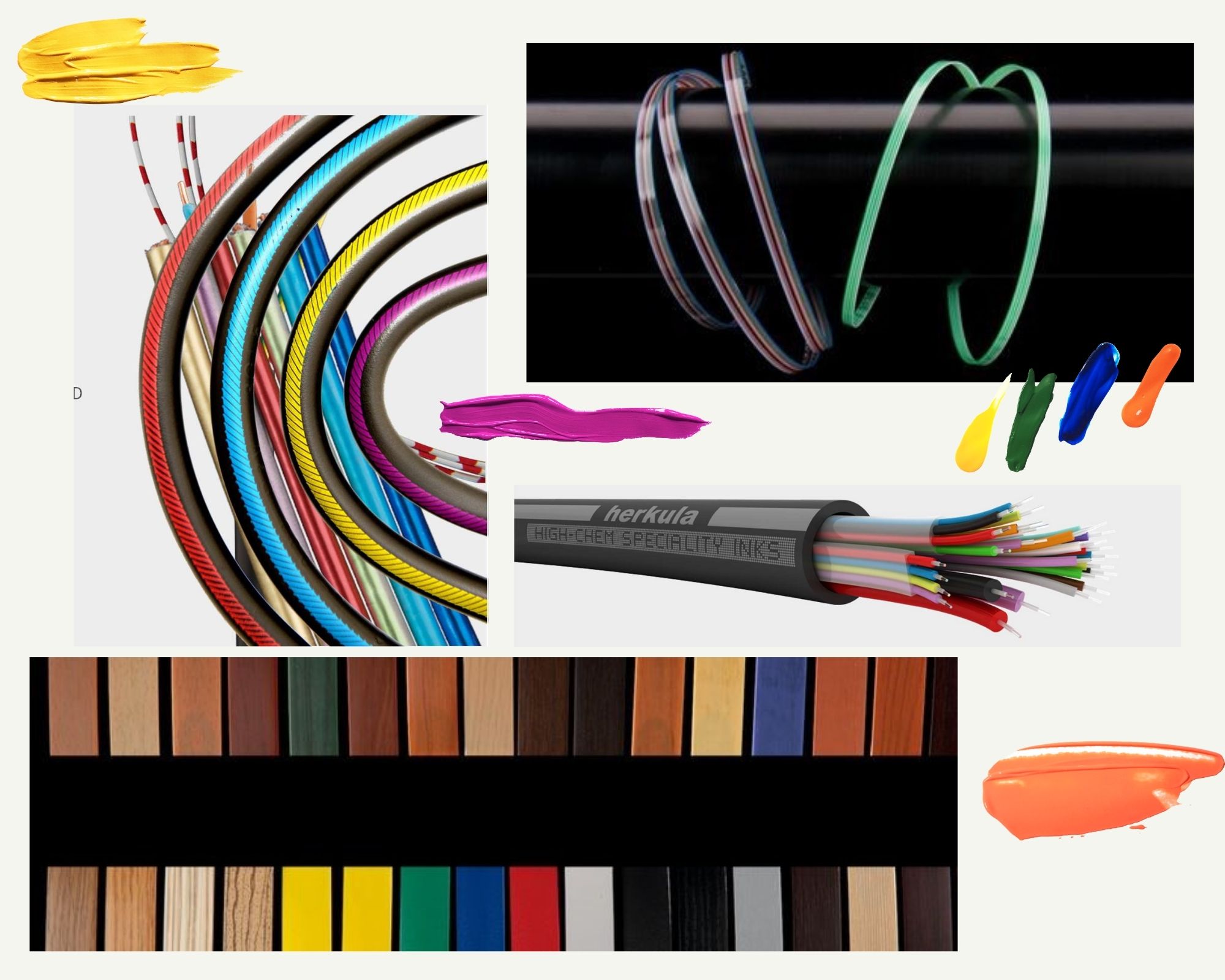

Single coating resin for tight buffer, outer coating resin for tight buffer. Balanced mechanical properties. Standard modulus Ribbon.

Optical Fibre Coating Resin

Optical fibre coating resin, medium-modulus and UV-curable, used for coating Tight Buffers, Compact Fibre Units and Ribbons.

UV and UV-LED resins for fibre optics complement and complement the FibreCoat ink line to meet the ever-increasing demand in the fibre optic coding industry.

UV resin for Tight Buffer

The 827F UV Tight Buffer resin from FARBWERKE HERKULA SA/AG can be used as a single coating or as a double coating (e.g. inner and outer).

The advantage of a single coating is that it is easier to process, while the combination of inner and outer coating results in better strippability for problem-free installation of the finished cable.

With our FibreCoat 827F material, line speeds of up to 1000 m/min can be achieved. Tight Buffer materials are available in different softnesses and colour shades.

Finally, some Tight Buffer materials are available with flame-retardant and high-temperature resistant properties.

UV resin for Compact Fibre Unit

To create a Compact Fibre Unit, a multi-fibre coating and curing system is required.

With this type of system, several fibres can be placed close together in a circular structure and coated with our UV or UV-LED matrix material.

A single CFU can contain up to 12 fibres. The line speed depends on the number of fibres.

The space-saving CFU structure allows optimal use of space and cable weight. Our materials offer excellent strippability for trouble-free installation of the finished cable.

Fibre Ribbon Resin

Standard Ribbon - To apply our matrix material onto the fibres, a ribbon line is required. With this ribbon line you can place the fibres next to each other and coat them with our UV matrix material.

A standard ribbon can hold up to 24 fibres and can be stacked up to a height of 22 layers. The line speed depends on the number of fibres.

The 827F series, specially designed for standard ribbon coating, offers excellent strippability for trouble-free installation of the finished cable.

Curing

Curing of FARBWERKE HERKULA SA/AG Fibre Optic Resin 827F takes place with high-pressure mercury vapour lamps or fusion lamps with nitrogen purge.

Stiffness remains unaffected up to 80°C.

Chemical and Mechanical Properties

FARBWERKE HERKULA SA/AG's FibreCoat 827F resin guarantees excellent balanced mechanical properties, excellent chemical resistance and is VOC-free.

Request More Information

Mohwinckel has been active in the cable industry market for over a century.

For 50 years Mohwinckel has been the official distributor in Italy of inks, paints and thinners produced by FARBWERKE HERKULA SA/AG. The Herkula inks we market include 3 different lines: Marcablo, Fibrecoat and InkJet.

Contact us for more information and a quotation.