What material are the thermal insulation sheets for the molds made of?

The family of CosTherm thermal insulation sheets produced by Isocos GmbH offers a complete range of special materials suitable for covering a wide spectrum of different applications distinguished by operating temperature, pressure exerted on the sheet and degree of thermal insulation required:

- panels based on a fabric of glass fibers impregnated in a highly insulating thermosetting resin matrix and highly resistant to high pressures,

- panels made from high quality mica sheets, pressed using a silicone resin suitable for pressure loads,

- calcium silicate sheets – asbestos-free – suitable for high temperatures up to 1000°C and low pressure loads.

Sectors of use for CosTherm insulating panels

The range of Costherm insulating thermal insulation sheets are suitable for different industrial production sectors:

- plastic and rubber injection,

- production of ennobled wooden panels,

- tool manufacturing,

- molds manufacturing.

How are CosTherm thermal insulation sheets used on industrial molds?

In plastic and rubber injection molding, as well as in continuously operating presses, short-cycle presses or floor presses for production systems in the production of veneered wood panels, the materials are subject to high thermal and mechanical loads.

ISOCOS specializes in the implementation of durable insulation concepts that guarantee uniform production quality.

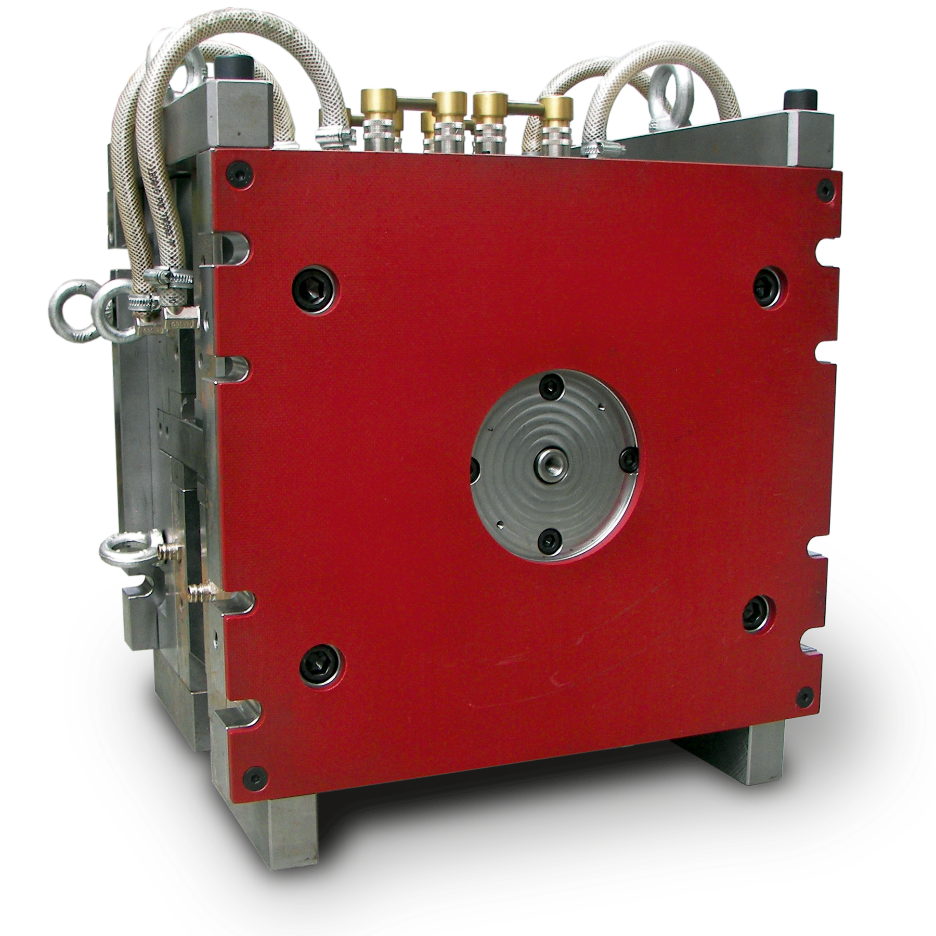

CosTherm insulating sheets are mounted between the press bed and the mold to reduce heat losses by conduction. Thus, the thermal insulation of the CosTherm insulating plates both reduces the heat exchange between one thermal cycle and the next, isolating the mold from the body of the press, and speeds up the production cycle times.

CosTherm thermal insulation panels can also be used to thermally insulate the side walls of the moulds, to reduce convective and radiative thermal losses with the surrounding environment. For this application, insulating panels from the Costherm range are used with lower compressive resistance and greater thermal insulation.

In studying the best solution suited to the customer, sandwich panels are also adopted where possible, in order to obtain the desired insulation and at the same time reduce costs for the customer.

The service includes the cutting of pieces to drawings as requested by the customer; using latest generation machines for the necessary processes, great dimensional precision in both lateral and thickness is guaranteed. The high degree of parallelism of the two planes of the insulating plate reduces stress during the working cycle of the press, increasing its useful life.

On request, it is possible to equip the CosTherm insulating sheets with a PTFE (Teflon) coating, if they are exposed to aggressive chemical agents during use.

CosTherm materials, due to their particular technical specifications, in addition to the sectors described, are used for various applications: e.g. as rubbing parts for conveyor belts, in stamping presses or in hose production systems.

Our service includes the tailor-made creation of details designed by the customer

Mohwinckel S.r.l. is the official distributor of CosTherm insulating sheets, made by the German Isocos GmbH. CosTherm sheets are designed to guarantee high standards of thermal insulation and quality in the industrial sector. The technical-commercial staff of Mohwinckel S.r.l. can provide any type of information, assistance and user guide to anyone interested in implementing them in their production process, ensuring customized solutions and continuous support.

Our staff is at your complete disposal, you can visit our complete offer of insulating materials click here.